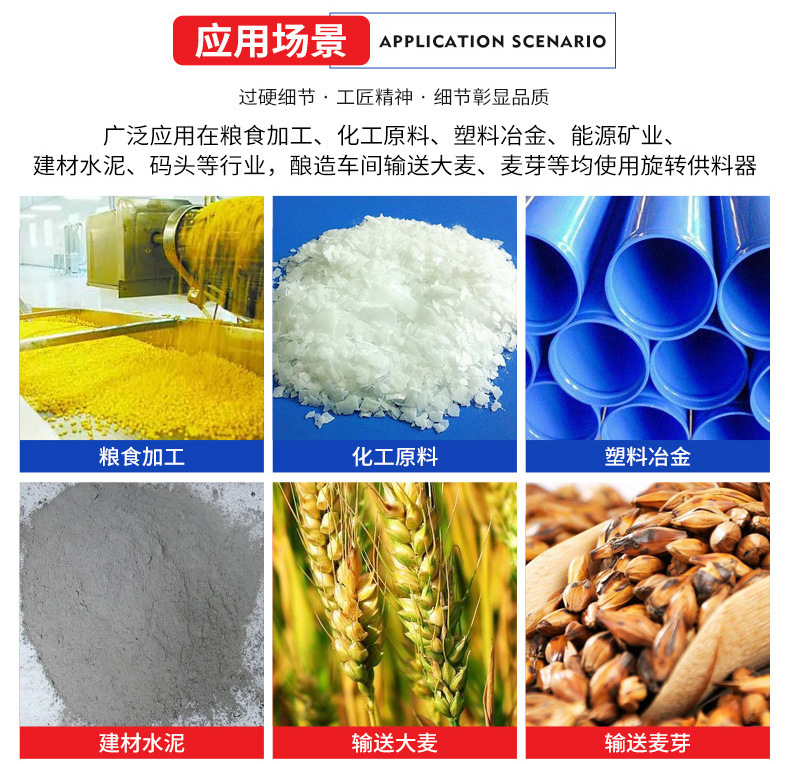

The main purpose of using a rotary feeder is to apply it to powder conveying systems for unloading, metering, dust removal, quantitative conveying, mixing, and packaging. Rotary valve is a common equipment used in the fields of pipeline fans, boiler fans, exhaust fans, etc. It belongs to a component of machines. So what are the structural characteristics of rotary valves.

1. Reliable performance. The special valve seat sealing ring design can automatically center, self overlap, and dynamically align with the valve core, which can improve the service life. Sealed metal bearings can prevent particle accumulation on the shaft surface and prevent valve core rotation.

2. Multiple operations are possible. The automatic centering valve seat sealing ring and sturdy valve core can achieve sealing when used in either forward or reverse flow direction. Using a backward flow direction, the outlet turbulence zone is far away from the valve seat sealing surface. In addition, the 90 degree stroke of the valve core also helps reduce the erosion between the valve core and the flowing medium, reducing the possibility of damage.

3. The rotating feeder is easy to install. The valve body with flange can be connected to different grades of pipeline flanges. To meet different design requirements, it is also possible to avoid exposed flange screws. The positioning surface and overall effect during installation are also good. We can also provide a compression type flanged valve body, which can be positioned with flange screws during installation

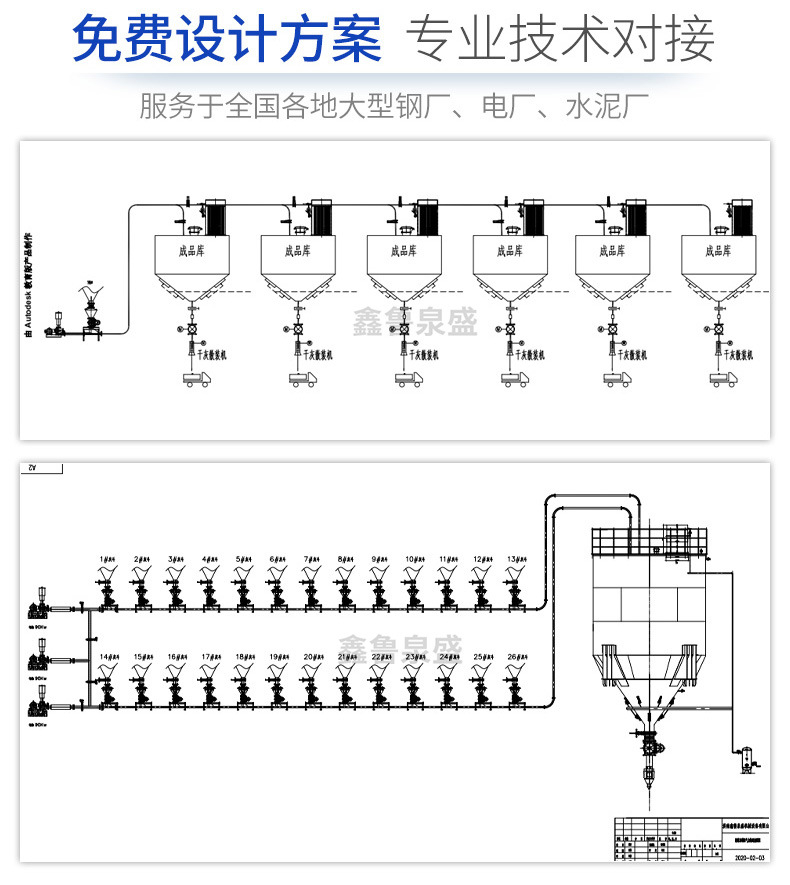

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd