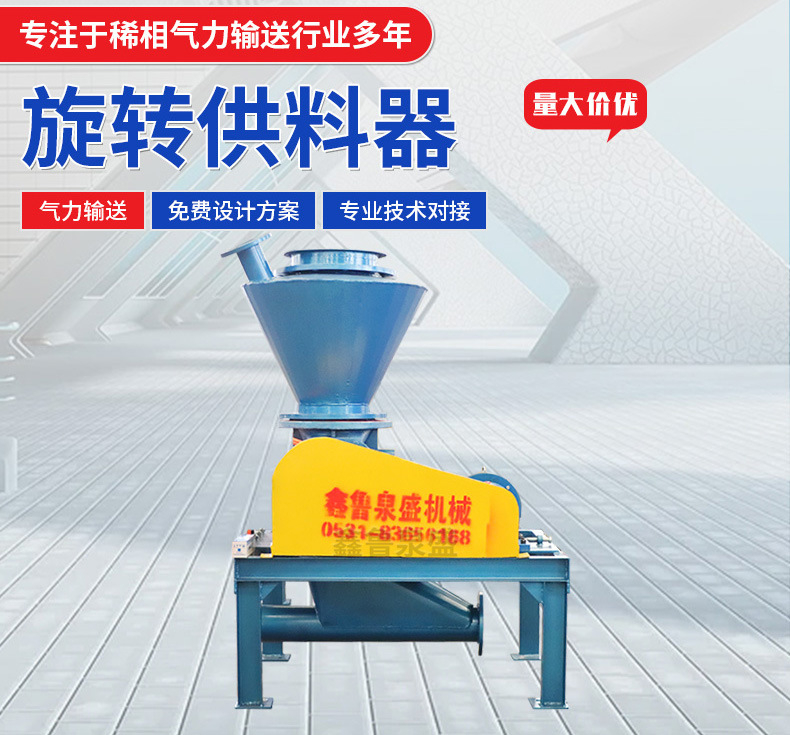

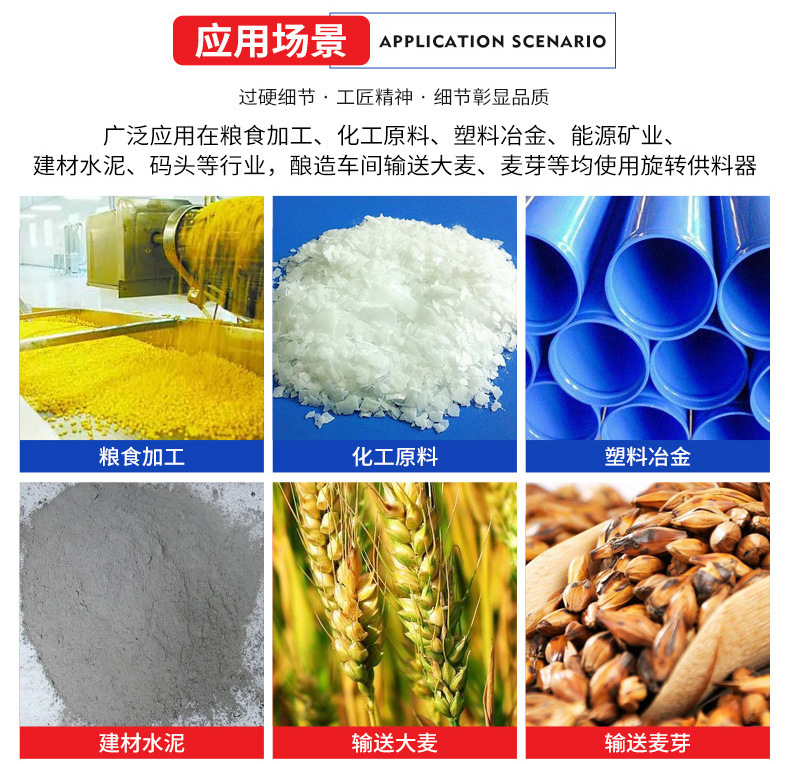

The rotary feeder is mainly composed of rotor and housing, impeller, seal, motor, gear and other components. It is used for feeding powdered materials and small particles. In the airflow feeding pipeline, the materials are separated and evenly fed. It is widely used in dry powder feeding systems in industries such as pharmaceuticals, food, cement, dust collection, and coal combustion.

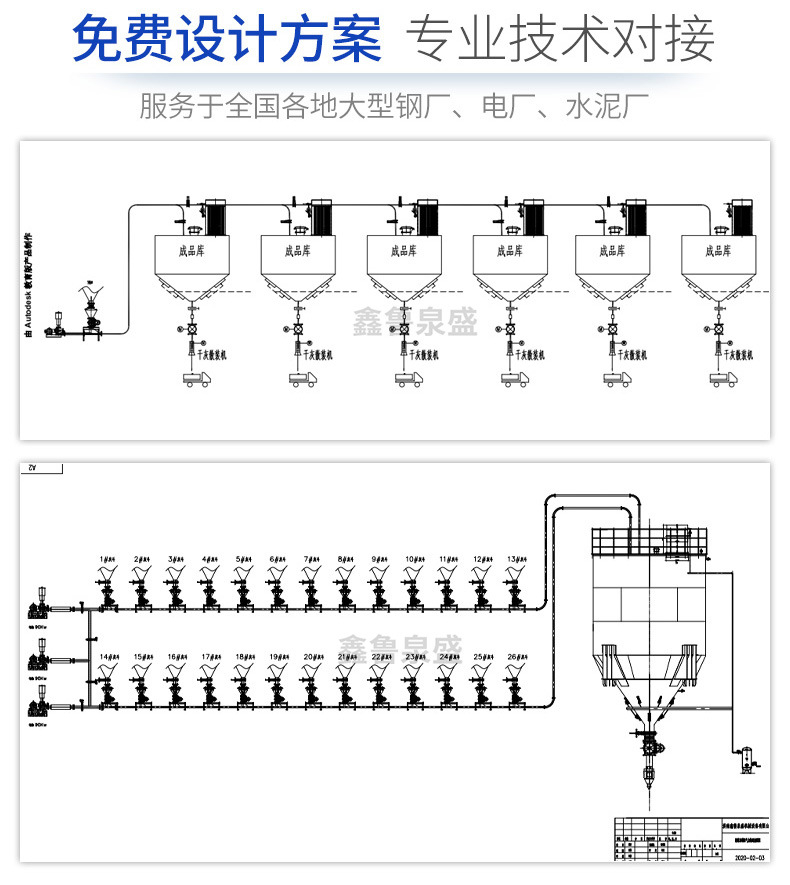

The rotary feeder is installed below the silo, and the material in the silo automatically falls onto the rotating impeller, which rotates along with the impeller to remove the shell. Due to the uniform rotation of the impeller and the gap between the impeller and the shell, the rotary feeder in the airflow feeding pipe network system can not only unload but also prevent airflow backflow, and the material operates normally under airflow transportation.

The standard conveying capacity of the rotary feeder can be selected according to the specification size of 2-100 cubic meters per hour. The main materials are carbon steel, stainless steel, steel, cast steel, cast iron, etc. It can adopt chain and direct transmission. The rotary feeder has the advantages of good sealing, compact and lightweight overall structure, easy layout and maintenance, simple flange connection, etc.

Puhui rotary feeder manufacturers can also customize production based on feeding quantity, installation size, material, specifications, and drawing usage requirements.

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd