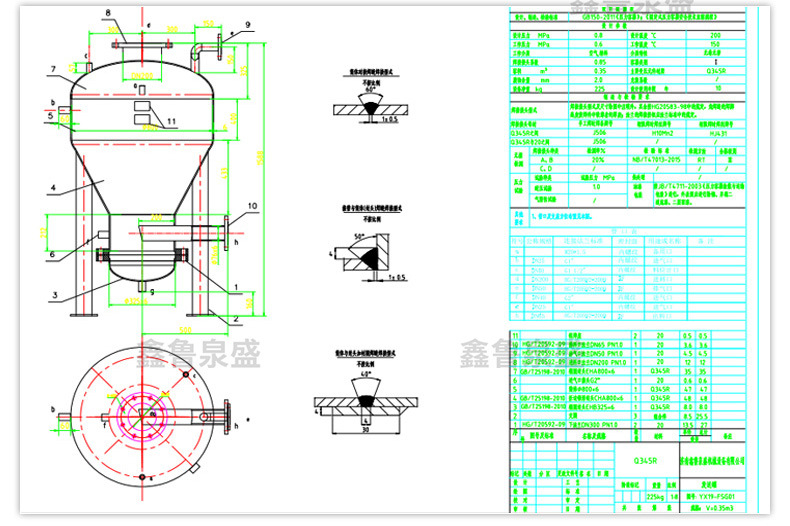

Warehouse pump, also known as bin pump, is a reliable dense phase dynamic pressure pneumatic conveying device that transports powdered materials under high pressure (about 700kPa or below).

There are two unloading methods for bin pumps, among which bottom discharge is the commonly used method, and the material in the tank is fluidized through conical surface inflation groove inflation, nozzle jet or other methods; Setting a fluidized inflatable plate (layer) at the bottom can allow the material to be discharged from the upper part of the tank. The distribution of transported gas on different input planes in the tank depends on the properties of the transported material.

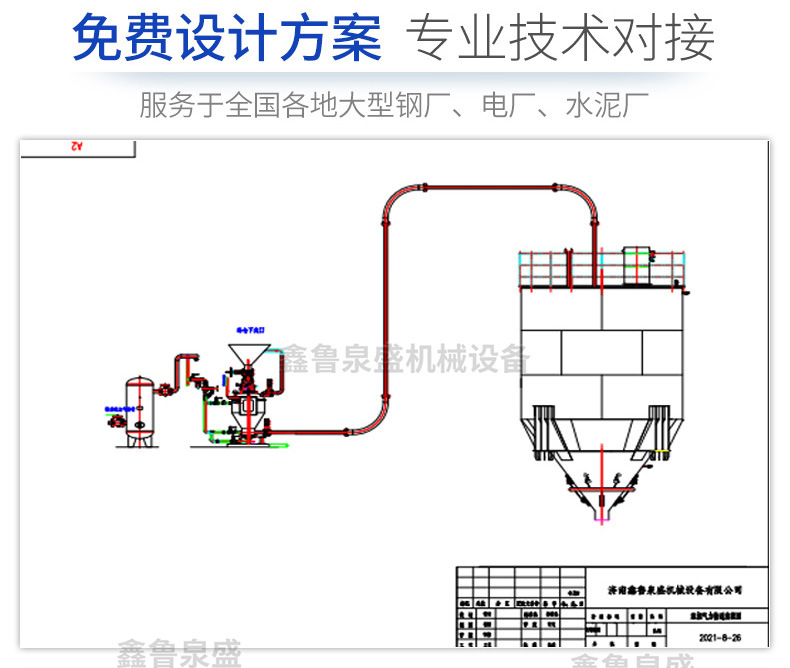

Operation process of warehouse pump

Open the feed valve and exhaust valve, and feed the bin pump at normal pressure until the level gauge sends out a full bin indicator signal;

Close the feed valve and exhaust valve, then open the high-pressure valve to pressurize the tank;

When the operating pressure is reached, open the conveying air valve and discharge valve, and the material begins to be conveyed;

The end of conveying is indicated by pressure switches, level gauges, or time relays. At this time, close the high-pressure air valve and discharge valve, so that all compressed air is used to blow the conveying pipeline; Simultaneously open the exhaust valve to reduce the pressure inside the tank to atmospheric pressure. After one work cycle is completed, another cycle continues.

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd