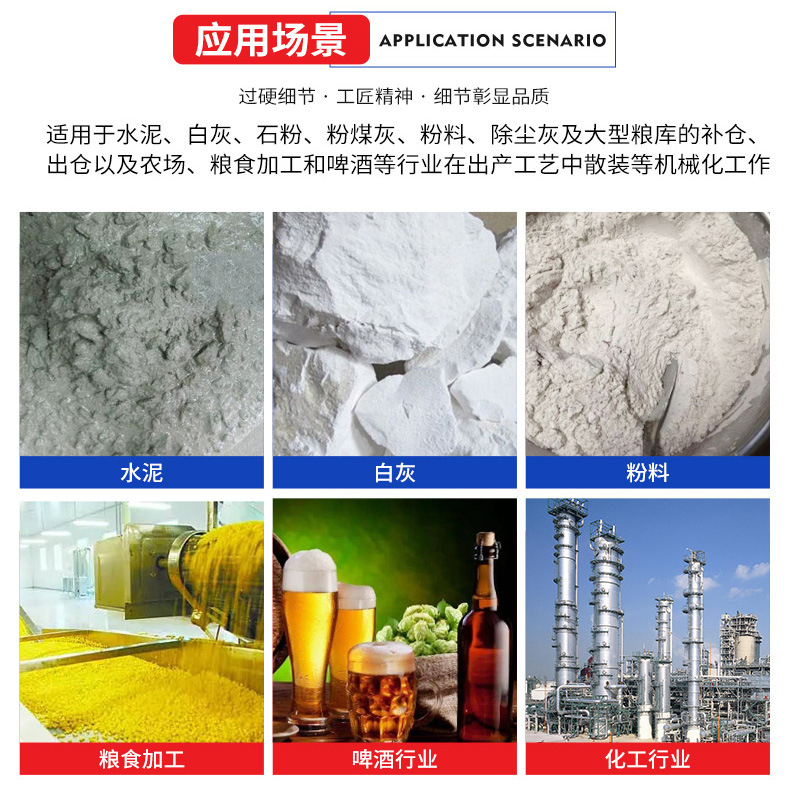

The negative pressure system of the dilute phase negative pressure conveying system mainly utilizes the vacuum generated by a vacuum type Roots blower (or vacuum pump) in a sealed pipeline, and feeds the material through a suction nozzle (or star shaped feeding valve and mixing acceleration chamber unit) with an air flow lower than the external atmospheric pressure. It is then mixed with air and sucked along the conveying pipeline to the cyclone separator for solid separation, achieving material conveying from multiple points in the low or bulk area to one or more points in the high area. When discharging conveyed materials from the receiving container, the rotary discharge valve can be used for continuous discharge, or the valve can be used for intermittent discharge.

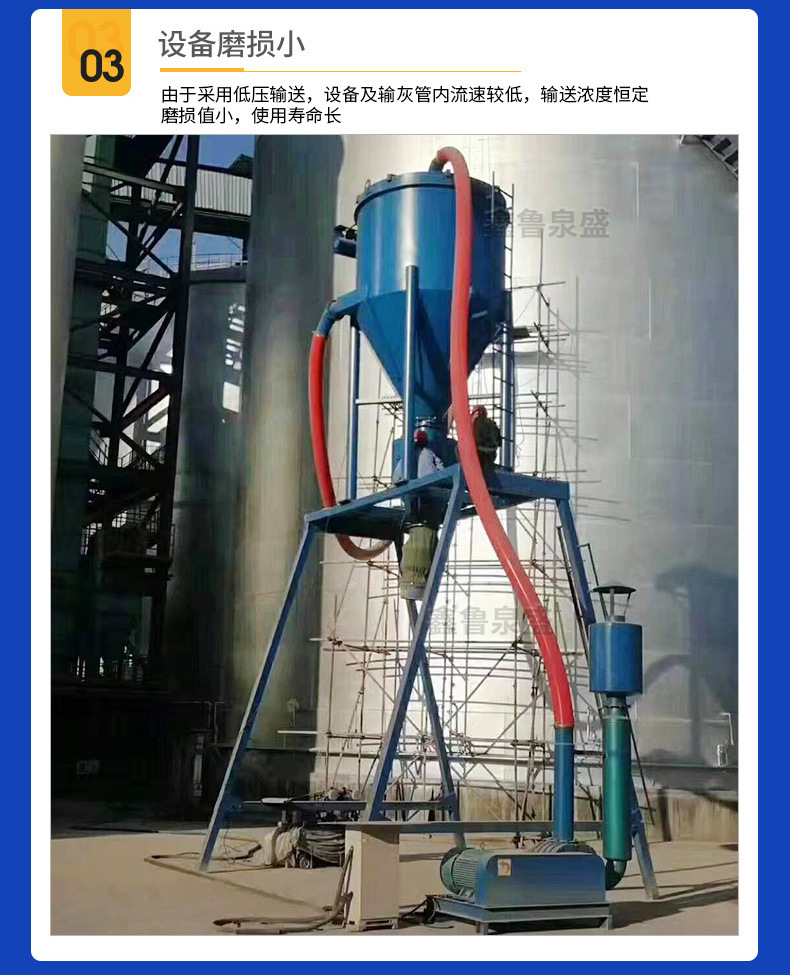

The initial starting speed of the system is about 10m/s, and the final speed reaches about 22m/s, resulting in a higher airflow velocity. The initial pressure of the conveying pipeline is usually below 0.1 MPa, while the tail end is close to atmospheric pressure. The medium for dilute phase transportation is generally air or nitrogen, and the material is suspended in the pipeline, with a transportation equivalent distance of up to 100 meters.

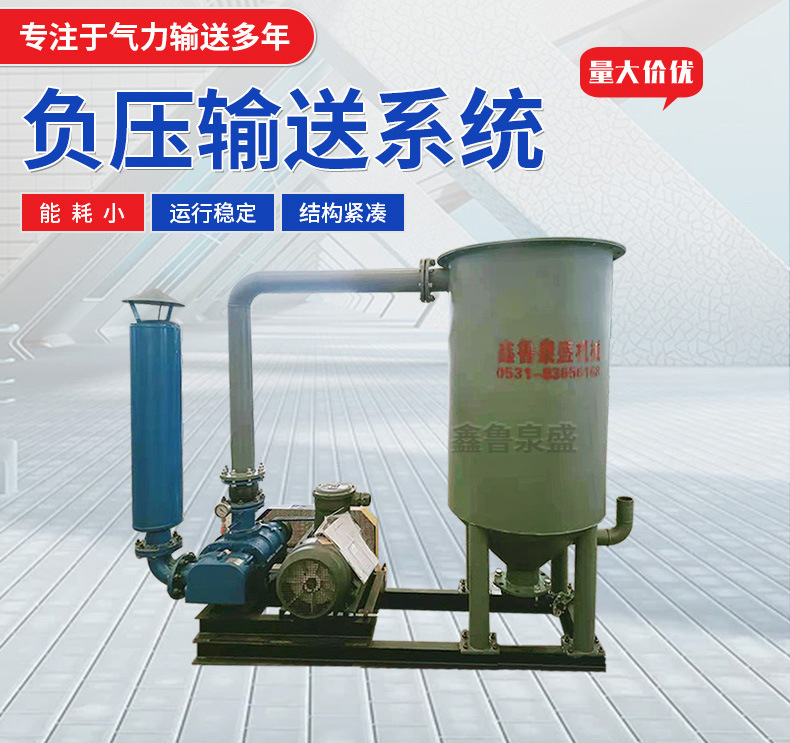

Its main components include mixing chamber, suction nozzle, star shaped feeding valve, cyclone separator, dust collector, Roots blower, electric control cabinet, etc.

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd

Jinan Xinlu Quansheng Machinery Equipment Co., Ltd